Cooling Methods and Lubrication Strategy

Metalworking machinery relies on friction plates that must endure significant mechanical load and intense thermal fluctuations. For this reason, engineers classify plates according to their cooling and lubrication method, distinguishing versions intended for operation in oil from those designed for dry operation. Oil-cooled plates dissipate heat more efficiently, maintain a stable friction coefficient, and provide longer service life, while dry-running plates deliver faster response and simpler assembly. Both configurations must support the clutch plate working principle, which depends on carefully balanced frictional behavior and controlled thermal expansion. When lubrication is matched correctly to mechanical demand, the system maintains predictable torque transfer and avoids premature wear during high-frequency cycles.

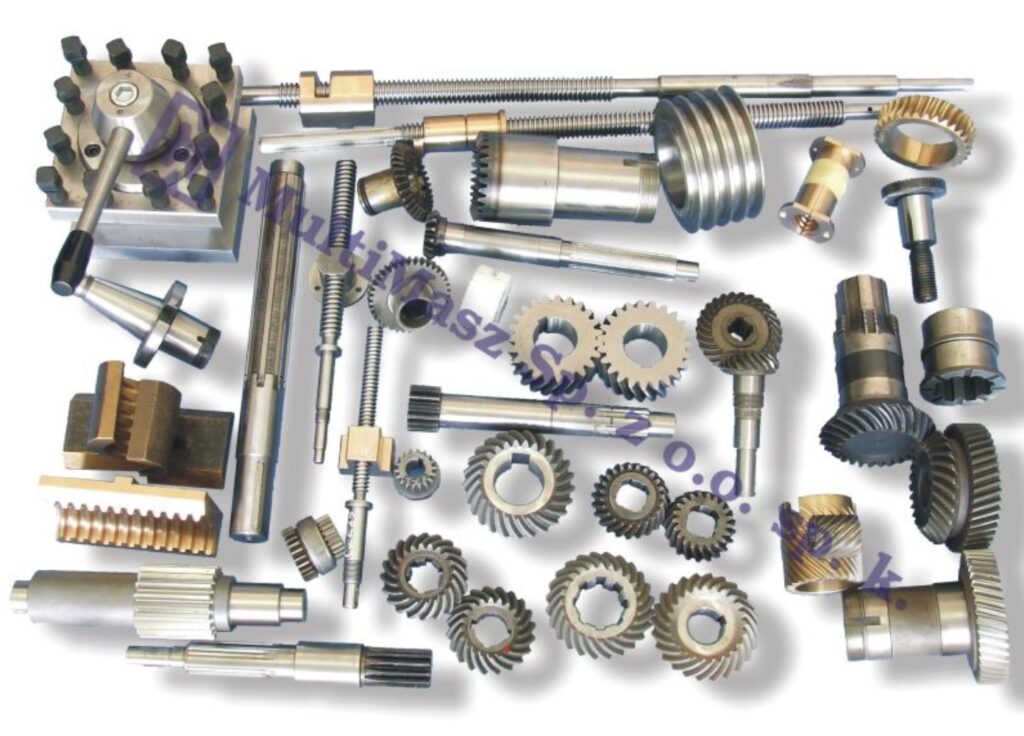

Reinforcement Through Hardened Steel Inserts

To enhance stability under repeated loading, many metalworking machines integrate inserts made of hardened steel into the friction plate assembly. Hardened steel not only increases resistance to plastic deformation but also preserves geometric precision during fast engagement and disengagement sequences. These inserts distribute pressure more uniformly across the active surface, improving torque consistency and reducing susceptibility to surface fatigue. Their durability is essential in environments where temperature spikes and rapid load changes occur continuously. By maintaining structural integrity throughout these dynamic conditions, hardened inserts uphold the mechanical balance required for reliable function, ensuring that operational forces align with the expectations shaped by the clutch plate working principle and its demand for synchronized mechanical response.

Mechanical Modifications for Faster Disengagement

Manufacturers often need clutches and brakes to disengage rapidly to support high-speed production lines, robotic operations, and synchronized machining sequences. To shorten release times, they apply specific mechanical modifications, the most common being the creation of “waved” plates. These precisely engineered undulations reduce contact area during release, enabling the plates to separate more quickly when actuated. Another strategy involves mounting expansion springs directly on the plates, producing controlled spacing that accelerates disengagement without compromising engagement torque. Both solutions aim to optimize responsiveness while maintaining consistent performance even under long-term stress. In many technical analyses, efficiency enhancements are directly associated with how effectively a system incorporates the clutch plate working principle, which influences every interaction between friction, pressure, geometry, and release timing within advanced industrial machinery.

Author Profile

-

Experienced software developers and IT professionals who have a wealth of knowledge and expertise in the field. Our team is dedicated to helping individuals and organizations keep their software applications running smoothly and efficiently, and we have a proven track record of helping clients optimize and maintain their applications.

Our team members have a wide range of experience working with different technologies and platforms, and we are constantly updating our skills and knowledge to stay current in the industry. We are passionate about what we do and are committed to providing the best service and support to our clients.

If you are looking for expert guidance on how to maintain and optimize your software applications, the Clean Application Lab team is here to help. Contact us to learn more about how we can assist you.

Latest entries

UncategorizedDecember 21, 2025OEE Monitoring System as the Foundation of Smart Manufacturing

UncategorizedDecember 21, 2025OEE Monitoring System as the Foundation of Smart Manufacturing UncategorizedDecember 18, 2025Choosing the Right Technology Partner for Sustainable Growth

UncategorizedDecember 18, 2025Choosing the Right Technology Partner for Sustainable Growth UncategorizedNovember 24, 2025Real-Time Insights and Measurable Impact in VR Training

UncategorizedNovember 24, 2025Real-Time Insights and Measurable Impact in VR Training UncategorizedNovember 22, 2025Clutch plate working principle in industrial applications

UncategorizedNovember 22, 2025Clutch plate working principle in industrial applications